——Fiber laser cutting machines and intelligent welding machines lead the new wave of intelligent manufacturing

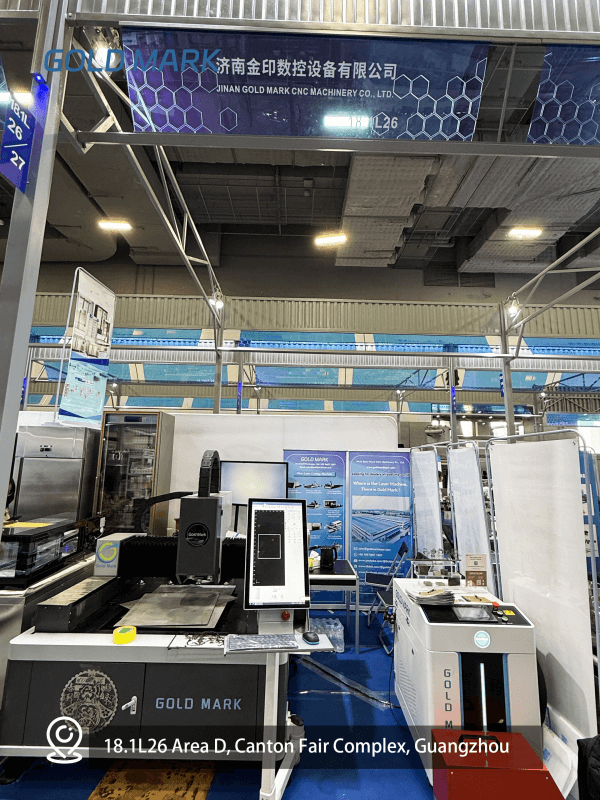

In April 2025, the 135th China Import and Export Fair (Canton Fair) was grandly opened at the Guangzhou Pazhou International Exhibition Center. As a benchmark enterprise for technological innovation in the global manufacturing industry, GOLD MARK CNC Machinery made a stunning appearance with its two core products, high-precision fiber laser cutting machines and fully automatic intelligent welding machines, showing the cutting-edge strength of China’s high-end equipment manufacturing to global merchants and becoming the focus of the exhibition’s intelligent manufacturing field.

Cutting-edge technology empowers and interprets the new height of “China’s Intelligent Manufacturing”

At this Canton Fair, the fiber laser cutting machine highlighted by GOLD MARK CNC Machinery has attracted widespread attention with its excellent performance. The equipment uses the world’s leading ultra-high-speed laser head and intelligent CNC system, with a cutting accuracy of ±0.03mm. It supports efficient processing of ultra-thin to ultra-thick plates (0.5-50mm) of various materials such as carbon steel, stainless steel, and aluminum alloy. It is equipped with AI dynamic compensation technology, which can optimize the cutting path in real time, and reduce energy consumption by 30% compared with traditional equipment. At the exhibition site, the complex special-shaped parts cutting process demonstrated by the equipment showed its wide application prospects in precision manufacturing fields such as aerospace and new energy vehicles.

The intelligent welding machine exhibited at the same time highlights GOLD MARK’s breakthrough in the field of automation. The equipment is equipped with a multi-axis linkage robot arm and a visual positioning system, supports TIG, MIG, and laser welding multi-mode switching, and the weld tracking accuracy is 0.1mm. With the independently developed welding parameter database, it can adapt to different materials and process requirements with one click. The on-site simulated automobile chassis welding scene, with its stable performance of 8 consecutive hours of zero-error operation, confirms its reliability in heavy industry and precision electronic manufacturing.

Global merchants gathered, and innovative achievements were highly recognized

At the booth, buyers from Germany, Southeast Asia, the Middle East and other places showed great interest in Jinyin equipment. A representative of a European industrial group said: “GOLD MARK’s laser cutting machine is comparable to the top European brands in terms of efficiency and intelligence, and the price advantage is significant. We are considering incorporating it into the supply chain upgrade plan.” It is reported that more than 20 intention orders were reached on the first day of the exhibition, and the contract amount exceeded US$8 million.